Director at Polymer Systems Technology Ltd

# Silicone 3D Printing Training

3D printing PST-4943 and PST-2631 static dissipative RTV or heat cure silicones have evolved.

These materials perform better from the process of 3D printing than conventional moulding achieving less than 100 ohm-cm resistivity.

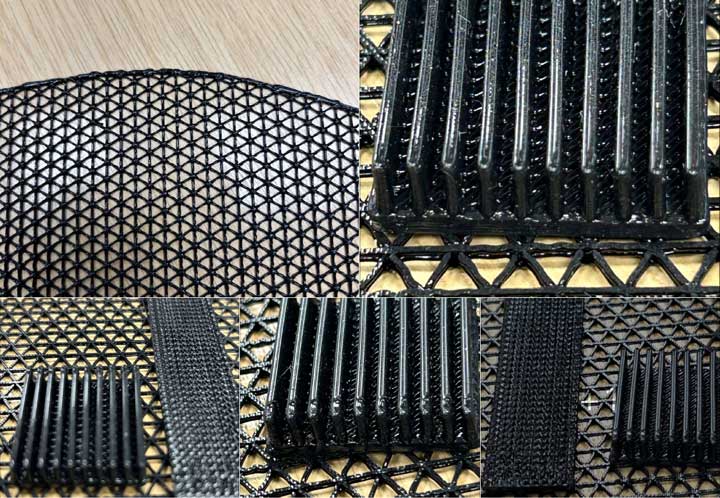

Creating matrices, objects and complex geometries for RFI and EMI shielding. Ideal for bespoke conductive gaskets and can be adhered to multiple substrates.

The benefits include reduction of weight, typically with 3D printing the infill can be between 30% to 100% and still provide the low resistivity.

Conventional moulding would always be a 100% infill , therefore the possibility of reducing weight in a multitude of aerospace and defence applications using silicone 3D printing.

A medical version is also available providing cytoxticity testing results.

These materials typically have a durometer of 45 shore A. Elongation of 275% with a tear strength of 50 ppi.

Visit our application laboratory and check out our pioneering technology and take advantage of our bespoke silicone 3D printing training.

Visit our silicone centre of excellence!